The Many Ways Trenchless Pipelining Can Save Your NOLA Sewer Line

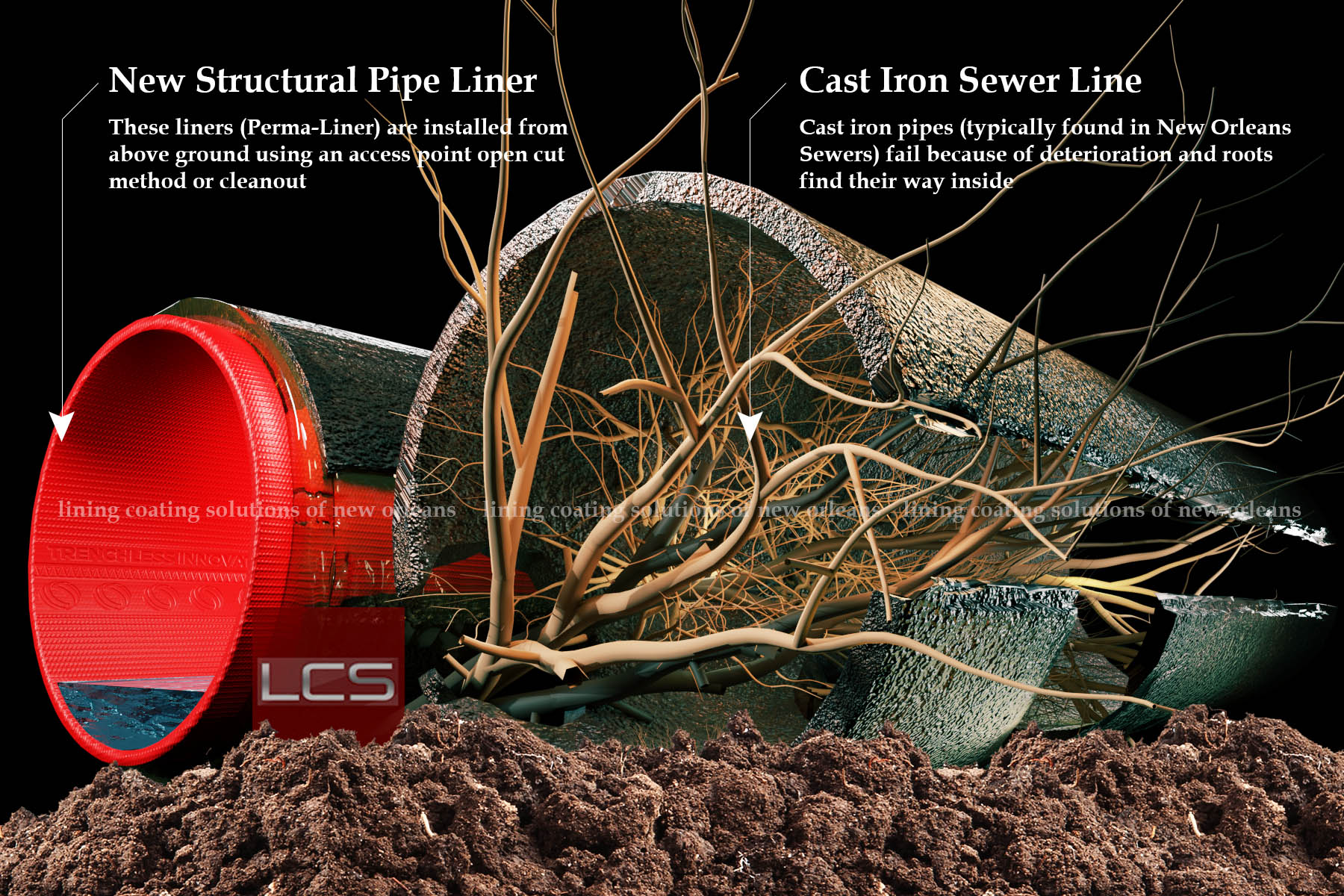

New Orleans, with its rich history and architectural heritage, is home to many buildings equipped with cast iron pipes. These pipes, once the standard for durability, are now often subject to corrosion, leaks, and breaks due to age and the city’s unique environmental challenges. This guide provides an in-depth look at cast iron pipe repair across major areas in New Orleans, emphasizing the need for specialized solutions that address the specific requirements of each district.

Trenchless Pipelining Methods:

Trenchless pipelining, a method for repairing and renewing existing pipelines without the need for extensive excavation, encompasses several techniques. These methods are designed to minimize disruption, reduce repair time, and are applicable to a variety of pipe materials and conditions. Here are the primary trenchless pipelining methods used in the industry:

- Cured-In-Place Pipe (CIPP)

CIPP involves inserting a resin-saturated felt tube into the existing pipe. The tube is then inflated and cured using heat (steam or hot water) or UV light, creating a new pipe within the old one. This method is suitable for repairing leaks, cracks, and improving structural integrity. Learn more about CIPP. - Pipe Bursting

Pipe bursting is used to replace brittle pipes that cannot be repaired. A bursting head is pulled through the existing pipe, fracturing it outward, while simultaneously pulling a new pipe into place. This technique is often used for upsizing pipes to increase flow capacity. - Slip Lining

Slip lining involves inserting a new, smaller pipe (usually plastic) into the existing pipeline and then grouting the space between the new and old pipes. This method is one of the oldest trenchless rehabilitation techniques and is used for structural repairs. - Spray Lining/Brush Coating

These methods involve applying a quick-setting epoxy, polyurea, or cementitious coating to the interior walls of the existing pipe using a spray or rotating brush system. This technique is used to restore pipe integrity, prevent leaks, and protect against corrosion. - Pull-in-Place (PIP)

The PIP method involves pulling a resin-saturated liner into place between two access points, then inflating and curing the liner as with CIPP. This technique allows for precise repairs over specific sections of pipe, including bends and transitions. - Inversion Lining

Similar to CIPP, inversion lining uses air pressure or water to invert a resin-saturated liner through the existing pipe. The liner is then cured to form a tight-fitting, jointless new pipe. Inversion is effective for long sections of pipe and can navigate bends. - Spiral Wound Lining

This technique involves winding a continuous strip of PVC or HDPE profile into the existing pipe. The profiles are wound in place using a winding machine, creating a new pipe lining that is structurally independent of the host pipe. - Point Repair

Point repair involves the localized repair of specific sections of pipe that are damaged. A short section of CIPP liner or a patch is applied to the damaged area, then cured in place. This method is efficient for addressing isolated issues without lining the entire pipe length.

Each trenchless pipelining method has its specific applications, advantages, and limitations, making the choice of technique dependent on factors such as the type and condition of the existing pipes, the nature and extent of the damage, accessibility, and environmental considerations.

Table of Contents