Spray Lining and Brush Coating Services in New Orleans

Lining Coating Solutions (LCS) provides specialized spray lining and brush coating services for pipeline rehabilitation and corrosion protection in New Orleans. These advanced, trenchless techniques are integral to our suite of solutions designed to restore and extend the life of aging or damaged pipelines. Suitable for both municipal and industrial applications, our spray lining and brush coating processes offer a minimally invasive, cost-effective alternative to traditional pipe replacement methods.

Understanding Spray Lining and Brush Coating

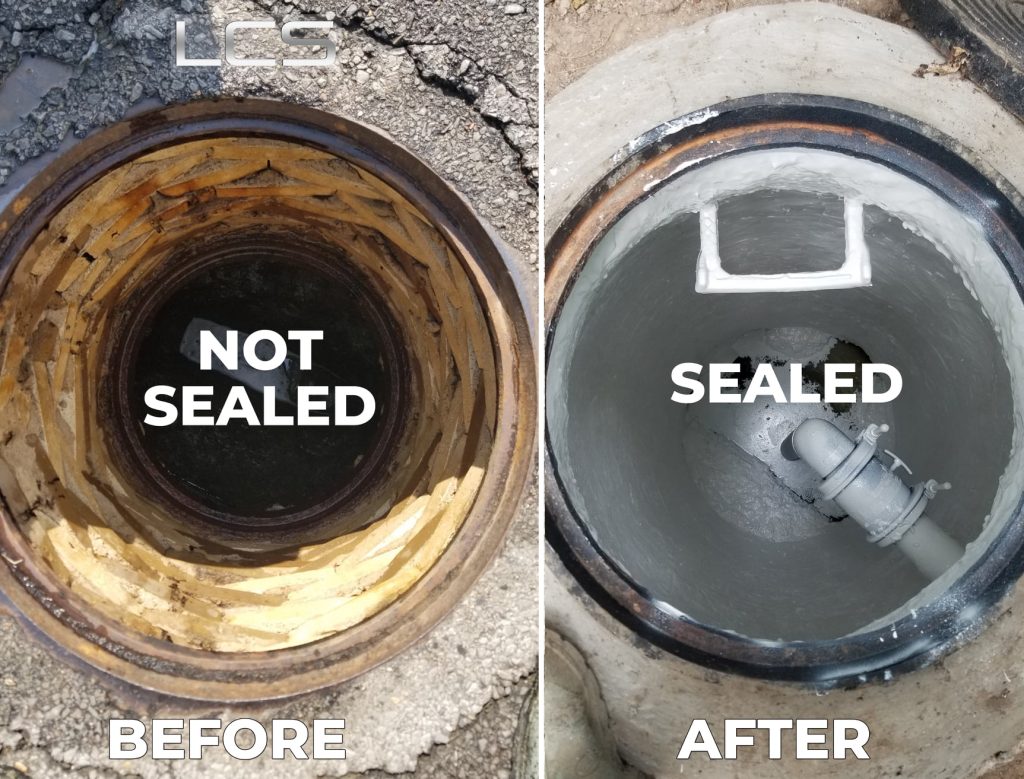

Spray lining and brush coating are methods used to apply protective coatings and linings to the interior surfaces of existing pipelines. These techniques are particularly effective for addressing issues such as corrosion, leaks, and surface degradation within pipes, offering a seamless, durable barrier that enhances the pipeline’s structural integrity and fluid flow efficiency.

Spray Lining

Spray lining involves the application of a liquid coating material to the interior walls of pipes using specialized spraying equipment. This method allows for a uniform, continuous layer of protection across the entire pipe surface, effectively sealing leaks and preventing corrosion. The coatings used in spray lining, such as epoxy, polyurea, or polyurethane, are selected based on the specific needs of the pipeline and the characteristics of the fluid it carries.

Brush Coating

Brush coating is a more targeted approach, where coating materials are applied manually with brushes or rollers. This method is particularly suited for localized repairs, touch-ups, or where more precise control over the coating thickness is required. Like spray lining, brush coating utilizes durable, corrosion-resistant materials that adhere strongly to the pipe interior, providing long-lasting protection.

LCS’s Process for Spray Lining and Brush Coating in New Orleans

Initial Pipeline Assessment

Our process begins with a comprehensive inspection of the pipeline using CCTV camera technology. This assessment helps us determine the extent of damage or degradation and the suitability of spray lining or brush coating as a rehabilitation solution.

Surface Preparation

Proper surface preparation is critical to the success of both spray lining and brush coating applications. LCS employs methods such as abrasive blasting or high-pressure cleaning to remove rust, scale, and other contaminants, ensuring optimal adhesion of the coating material to the pipe interior.

Application of Coatings

For spray lining, LCS uses state-of-the-art spraying equipment to apply a uniform coating to the pipe interior. The equipment is carefully calibrated to control the thickness and ensure even coverage. For brush coating, our skilled technicians apply the coating material manually, focusing on achieving a smooth, consistent layer, particularly in areas requiring targeted attention.

Curing and Quality Assurance

Once applied, the coating material undergoes a curing process, transforming into a hard, durable lining that fully bonds to the pipe interior. LCS conducts a final inspection to ensure the integrity and uniformity of the coating, using techniques such as ultrasonic thickness testing and visual inspection.

Benefits of LCS’s Spray Lining and Brush Coating Services

- Reduced Disruption: As trenchless methods, spray lining, and brush coating minimize the need for excavation, significantly reducing disruption to the surrounding area and daily operations.

- Cost Efficiency: These methods offer a cost-effective alternative to pipe replacement, particularly for addressing localized issues or providing an added layer of protection against future corrosion.

- Extended Pipeline Lifespan: The coatings and linings applied through these methods enhance the structural integrity of pipes and protect against corrosive elements, effectively extending the service life of the pipeline.

- Versatility: Suitable for a wide range of pipe materials and diameters, spray lining and brush coating can be tailored to meet the specific needs of various applications, from water and sewer lines to industrial conduits.

Serving New Orleans with Advanced Pipeline Solutions

LCS is committed to delivering high-quality, durable pipeline rehabilitation solutions to New Orleans. Our spray lining and brush coating services are part of our broader effort to provide innovative, minimally invasive techniques that meet the unique infrastructure challenges of the city. Whether addressing corrosion, leaks, or enhancing pipeline longevity, LCS’s expertise ensures that New Orleans’ pipelines continue to perform efficiently and reliably.